Design of flexible structures in 3D printing – licentiate presentation

3D printing, or additive manufacturing as it is also called, is a useful alternative to traditional manufacturing methods. However, the unique benefits also come with limitations and difficulties. Some of the challenges are related to printing orientation and geometry deviations, which is of great importance in order to be able to take full advantage of additive manufacturing.

– Published 29 January 2024

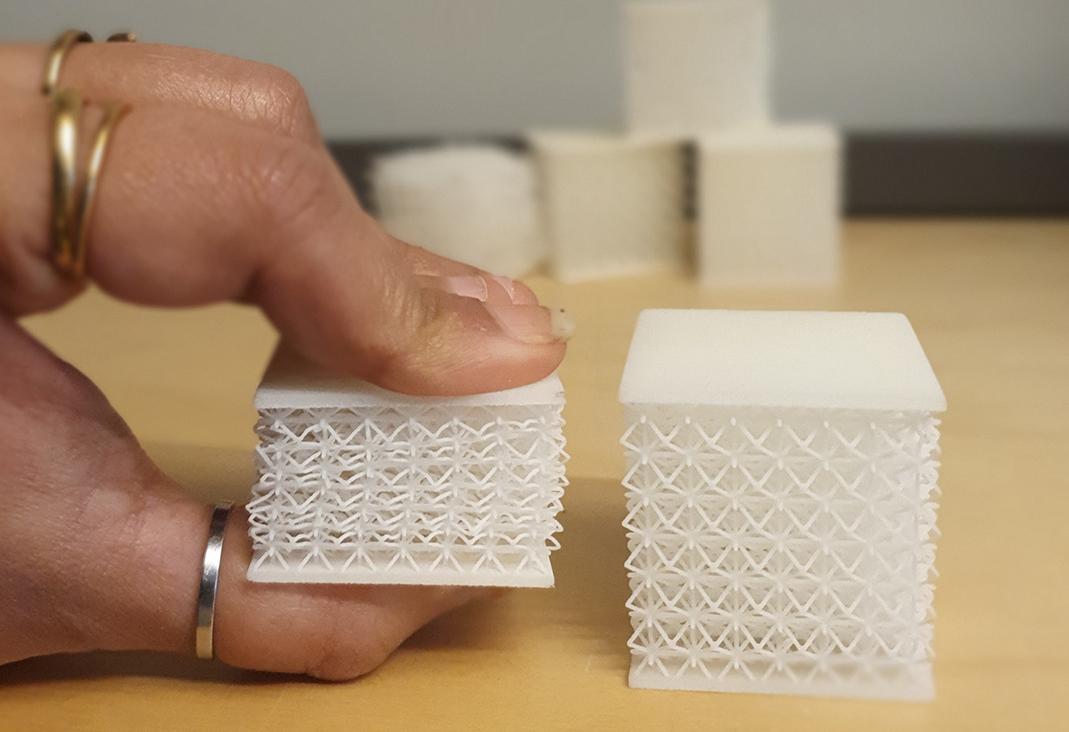

While much of the development so far has focused on stiffness, flexibility is a less explored area. Flexible structures are often used, for example, in robotics for movement, orthotics in healthcare, and shock-absorbing cranial helmets. One type of flexible structure is lattice structure which helps to make the printed parts lighter and stronger and allow us to tune mechanical properties as desired. However, even though we have knowledge about the lattice structure itself, there are still knowledge gaps linked to the interplay between the design of lattice structures and design for additive manufacturing (DfAM).

Satabdee Dash, who is a doctoral student in Innovation at the Faculty of Engineering, wants to use her research to increase knowledge about how to design flexible lattice structures tailored for 3D printing.

Welcome to the presentation of Satabdee Dash's licentiate thesis Design of flexible lattice structures: a design for additive manufacturing perspective.

1 February at 10.15 at IKDC, Sölvegatan 26 in Lund, room 304, or on Zoom: https://lu-se.zoom.us/j/65442398504

Opponent is Massimo Panarotto, Senior Researcher in Product Development and Industrial and Materials Science at Chalmers University of Technology.

Do you want to know more about the research?

Contact Satabdee Dash:

Satabdee Dash — Lund University

Download the licentiate thesis from Lund University research portal:

Design of flexible lattice structures: a design for additive manufacturing perspective — Lund University