Intelligent packaging

Intelligent returlåda

Livsmedelsindustrin är ett av de områden som har stora utmaningar för att arbeta mer hållbart, därav är behovet av innovationer stort. Matsvinn är en utav de allvarliga och stora problem som branschen, liksom för samhället som helhet, står inför. Lunds universitet tillsammans med Svenska Retursystem, Bergendahls, Bring SCM, Orkla foods, Everfresh, Sony Mobile Communications och Ångpanneföreningen har i detta Vinnovafinansierade projekt utforskat en potentiell innovation benämnd Intelligent Returlåda.

Vi har genom fallstudier och fälttester funnit potential för helt nya förutsättningar för effektivare, miljöanpassade och säkrare varuflöde som möjliggör nya tjänster för alla aktörer i livsmedelsindustrin. Genom att integrera sensorer i SRS returlådorna möjliggörs aktörer att i realtid få insikt i en varas hantering och kylkedja, och ta sitt ansvar för varuflödet och minimera eventuella problem, så att en vara som producerats verkligen når slutkonsument med bästa möjliga kvalité.

De mest intressanta områdena, enligt deltagarna i denna studie, är spårbarhet i realtid, mer tillförlitliga och trovärdiga temperaturmonitorering samt mer effektiva processer, inte minst i överlämnandet av varor mellan aktörer. Med implementeringen av intelligenta returlådor är uppskattningen att det skulle kunna minska matsvinn och andra kvalitetsbristkostnader i försörjningskedjorna på mellan SEK 30-300 milj kr/år.

Samtidigt har ett antal hinder också identifierats såsom en branschkultur med motvilja att dela information. Ett annat hinder är vikten av och utmaningen med att fastställa vem som äger och vem som har tillgång till vilken information och när. Det har också identifierats som en utmaning att få de stora dagligvaruaktörerna att bli intresserade, för det är de som har mest makt i kedjorna idag. Utan deras intresse och användande av de intelligenta returlådorna kommer inte erforderliga effekter att uppnås och inte heller några gemensamma implementeringssatsningar.

DynahMat – Dynamic shelflife for minimized food waste

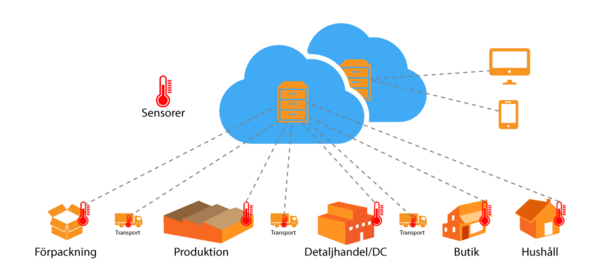

Resource utilization in the food supply chains today is far from optimal and has great potential for improvement when it comes to food waste, inefficiencies and sustainability. The DynahMat project set out to develop and provide roadmaps and implementation strategies for an open system solution that enables the integration and interconnection of different sensor solutions, quality prediction, communication solutions, databases, business systems and user applications. With specific focus on the static date labeling system the project has explored ways to minimize food waste, supply chain inefficiencies and how to contribute to a more sustainable industry.

DynahMat has developed an open system solution concept that enables the integration and interconnection of different sensor solutions, quality prediction, communication solutions, databases, business systems and applications. With further implementation of DynahMat actors in the food industry will be provided by solutions to guarantee an efficient flow of wholesome food and minimize waste. In the project the following results have been gained:

- A cloud solution with web-based user interfaces and open Application Programming Interfaces (APIs) for sensor input, prediction models and data output.

- A parameterized solution for prediction models integrated to the cloud system

- A temperature sensor solution based on wireless communication and a mobile phone application for usage in the supply chain as both gateway and user interface to personnel

- One mobile phone application for consumer usage in retail

- Strategies and road-maps for further development and implementation

The DynahMat concept could act as the foundation for a common infrastructure for traceability, sensors and consumer applications in food supply chains. By setting the standards in terms of APIs and data structures several different sensor solutions as well as other services could co-evolve and develop the whole food industry into a more digitalized paradigm. Consequently, with a common infrastructure a meat producer could buy specific sensors with temperature and (in the future) direct quality and safety measurements, while a fruit wholesaler rather would like to have sensor solution with mechanical impact, temperature and humidity.

Hence, with an industry wide effort based on DynahMat a new paradigm for the entire food industry could be made possible. A paradigm built on digitalization and accurate and accessible data that could lower food waste, improve effectiveness and efficiency in food supply chains. Most importantly, it would enable sustainable development as resource utilization and quality improvement could be targeted collaboratively among food chain actors.

DynahMat project adopted a multidisciplinary approach with expertise in food microbiology, simulation technology, electrical measurements, packaging technology, logistics, innovation, SCM and distributed information systems together with actors from all tiers in the value chain. With all stages of the value chain, including consumer representatives, we have had a unique opportunity for open discussions, to learn from each other and thus been able to think in new ways and to take advantage of solutions and ideas that arose during the project implementation. The project has been carried out in close connection to practice with several field tests in three product streams with a focus on chilled, packed and perishable foods with a short shelf life and high product value. The project has been organized into six work packages (WP) which projects essential aspects tested, developed and deepened. These were: WP1 Exploration driven logistics and packaging innovation, WP2 Evaluation of sensor technology, WP3 Modelling and prediction of shelf life, WP4 Evaluation of system solutions from an ICT perspective, WP5 Implementation challenges in the food supply chain, WP6 Consumer confidence, honesty and legislation.

Den intelligenta returlådan möjligggör:

- Ökad produktsäkerhet

- Förlängd hållbarhet på livsmedel

- Säkrare e-handelslösningar

- Nya konsumentlösningar